DESIGNING AN EFFICIENT CONTROL PANEL: KEY FACTORS

4/5/2024 - Asif Mansoori

4/5/2024 - Asif Mansoori

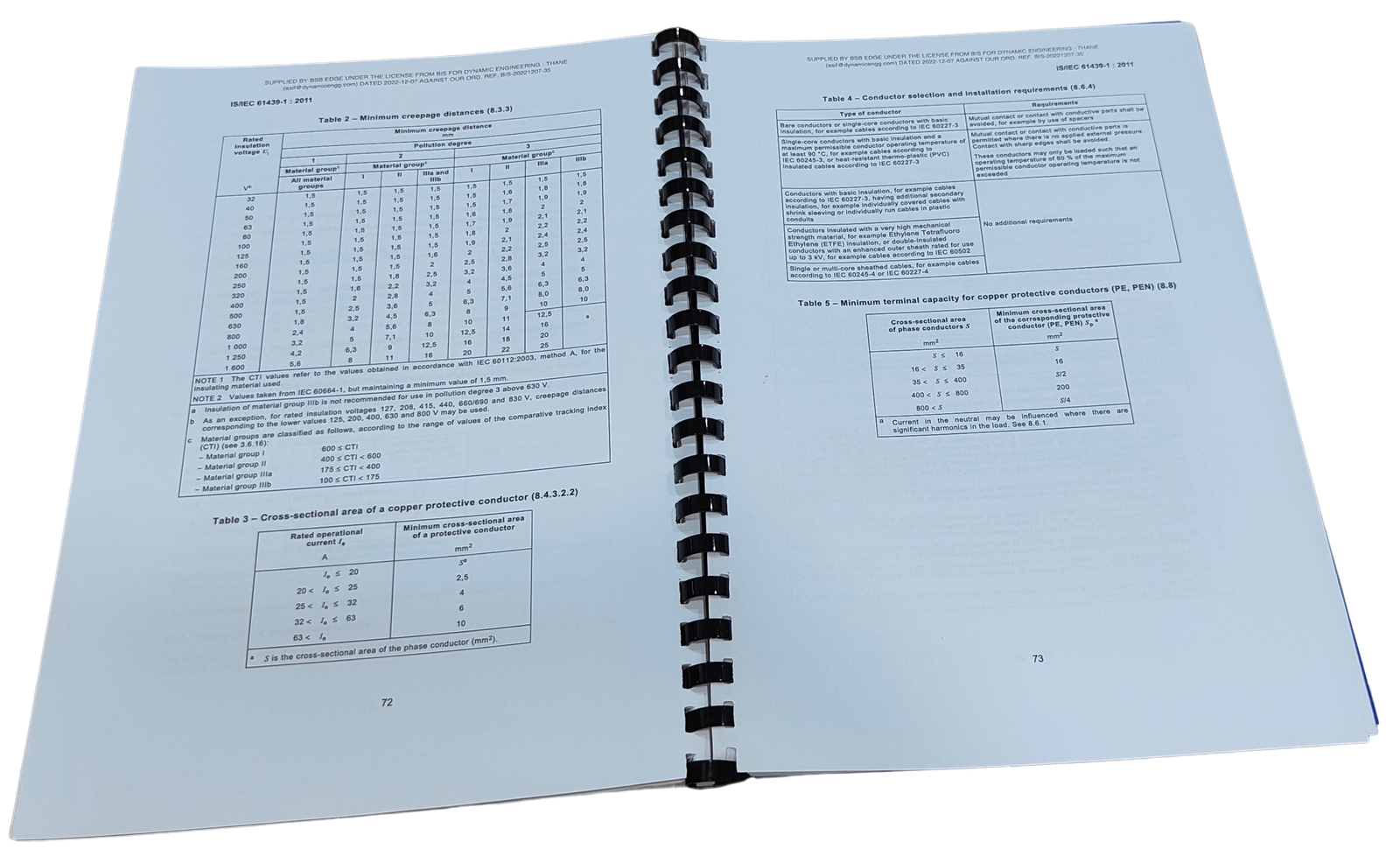

Compliance with Standards: Ensure the design complies with relevant standards and regulations, such as NEC, UL, IEC, and NFPA. Hardcopies & PDF of these standards can be ordered online from BSB edge. This is the first step towards safety in

design.

Proper Grounding and Bonding: Essential for safety and the prevention of electrical shocks and equipment damage.

Overcurrent Protection: Use appropriate fuses, circuit breakers, and other protective devices to prevent overloading

and short circuits.

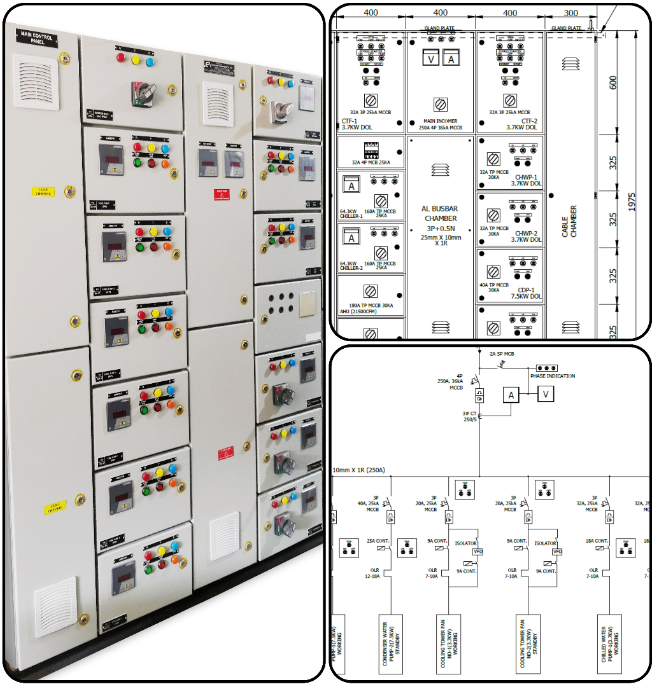

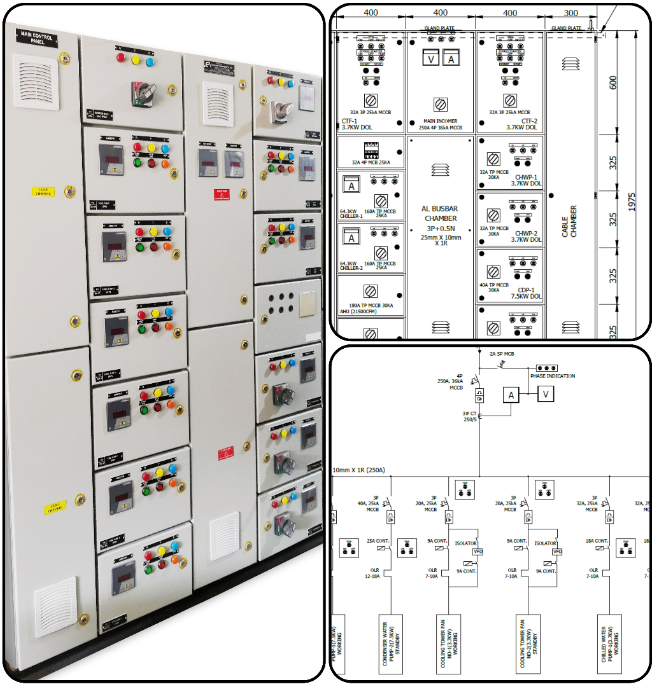

Component Placement: Arrange components logically to facilitate easy access, troubleshooting, and maintenance.

Adequate Spacing: Ensure sufficient space between components to prevent overheating and allow for proper airflow.

Panel Size: Select a panel size that accommodates all components with room for future expansion. Usually, it is taken as 20% of the overall consumed space inside any cubicle.

Ventilation: Include air vents, fans, or panel ACs to manage heat dissipation and prevent overheating. It is calculated as per collective heat dissipation of all components mounted.

Heat Sinks: Use heat sinks or thermal pads for components that generate significant heat.

Cable Routing: Plan the routing of cables and wires to minimize interference and signal loss.

Labelling: Clearly label all wires and components for easy identification and troubleshooting.

Cable Trays and Ducts: Use cable trays, ducts, or raceways to organize and protect cables.

Busbars and Terminal Blocks: Use appropriate busbars and terminal blocks to ensure reliable power distribution.

Voltage Levels: Clearly separate different voltage levels to avoid accidental contact and ensure safety.

Quality and Compatibility: Choose high-quality components that are compatible with each other and suited to the application. Some designers are forced to compromise on the quality due to cost pressure from client but it is duty of designer to prefer safety

& compatibility over cost.

Future-proofing: Select components that allow for easy upgrades and scalability. This can be selection of busbar of higher capacity, providing extra terminals & space for more components or providing components with communication facility

for BMS etc.

PLC and HMI: Ensure proper integration of Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) for effective control and monitoring.

Communication Protocols: Use standardized communication protocols (e.g., Modbus, Ethernet/IP) for reliable data exchange between devices.

Ingress Protection: Choose enclosures with appropriate IP ratings to protect against dust, water, and other environmental factors.

Material Selection: Select materials (e.g., stainless steel, coated steel) based on the operating environment (e.g.,

corrosive, humid). Electromagnetic Compatibility is also considered in some cases & special enclosures are used.

Accessibility: Design the panel for easy access to all components to simplify maintenance and repairs.

Documentation: Provide comprehensive documentation, including wiring diagrams, component specifications, and maintenance instructions.

Backup Systems: Incorporate redundant power supplies, PLCs, or critical components to ensure continuous operation in case of failure. This off course incurs additional cost with increased reliability.

Quality Control: Implement thorough testing

and quality control procedures to ensure the control panel’s reliability.

Budgeting: Balance cost considerations with quality and performance requirements. It is up to designer to go hand in hand with cost & quality.

Standardization: Use standardized components and modular designs to reduce costs and simplify assembly.

In many cases though, cost doesn’t allow to go with modular design & decision about this depends on the future plan & budget of the end user.

Manuals and Guides: Provide detailed manuals and guides for operation, troubleshooting, and maintenance.

Training: Offer training sessions for operators and maintenance personnel to ensure they are familiar with the control panel’s functions and

safety procedures.

As-built drawings: Provide corrected & updated as-built version of the documents & drawing to end-user & operations team.

Scalability: Design the control panel with future expansion in mind, allowing for additional components and capabilities as needed. If there’s no future expansion plan, this can be avoided to save cost on the costly items like copper busbars.

Flexible Design: Use modular components and expandable systems to facilitate upgrades and changes. Interchangeability of the components or modules is needed when downtime of entire system is not allowed during operations & this factor along

with cost is also to be considered while going for flexibility.

By considering these important aspects, one can design an efficient electrical control panel that is safe, reliable, and easy to maintain, meeting the specific needs of the application while also allowing for future growth and changes. At

Dynamic Engineering, we engineer to order all types of control panels keeping in mind above factors but only when it is needed. A good design goes hand in hand with cost, quality & reliability.

Copyright ©2024 Dynamic Engineering - All Rights Reserved